Autonomous Rover

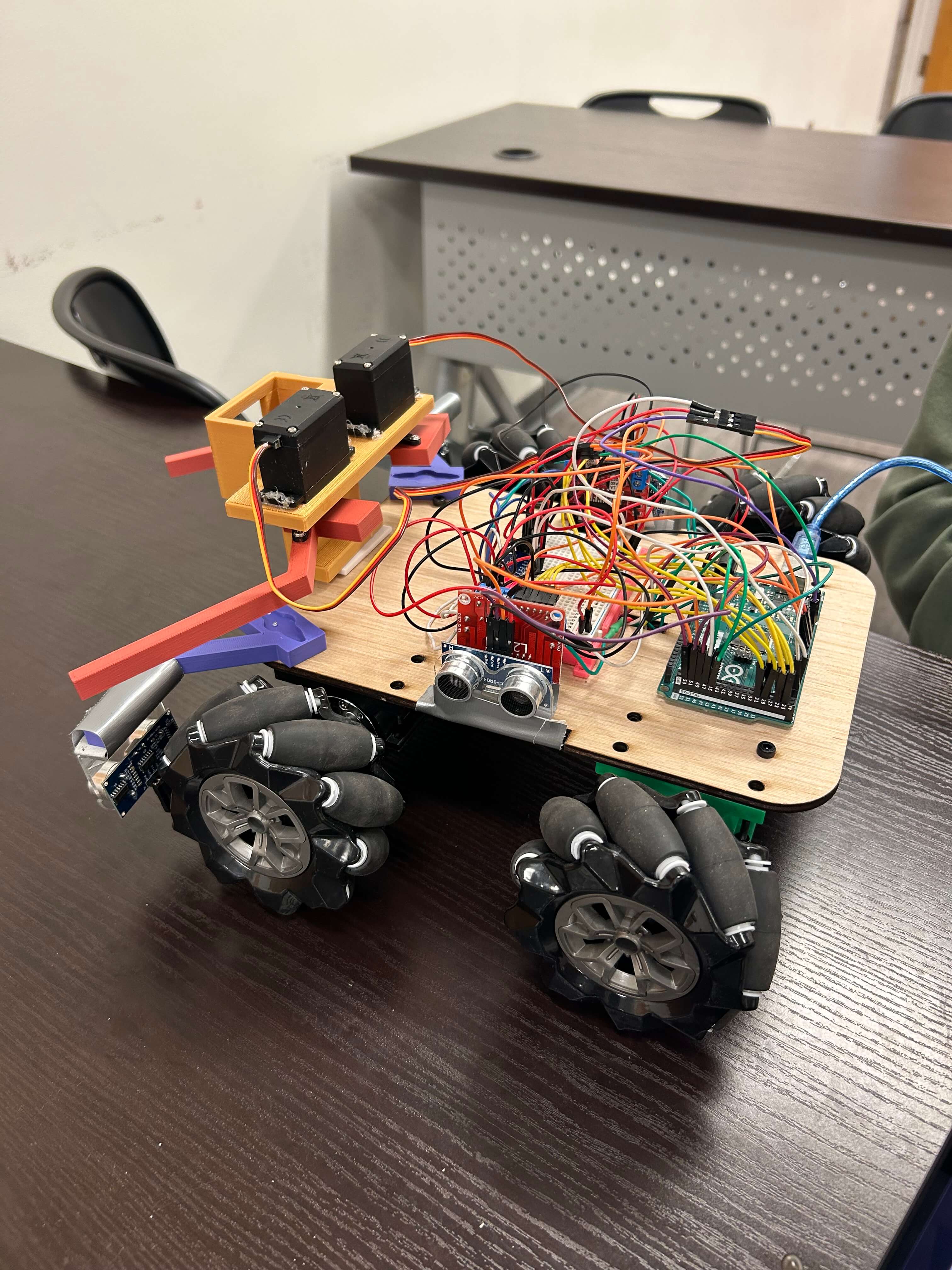

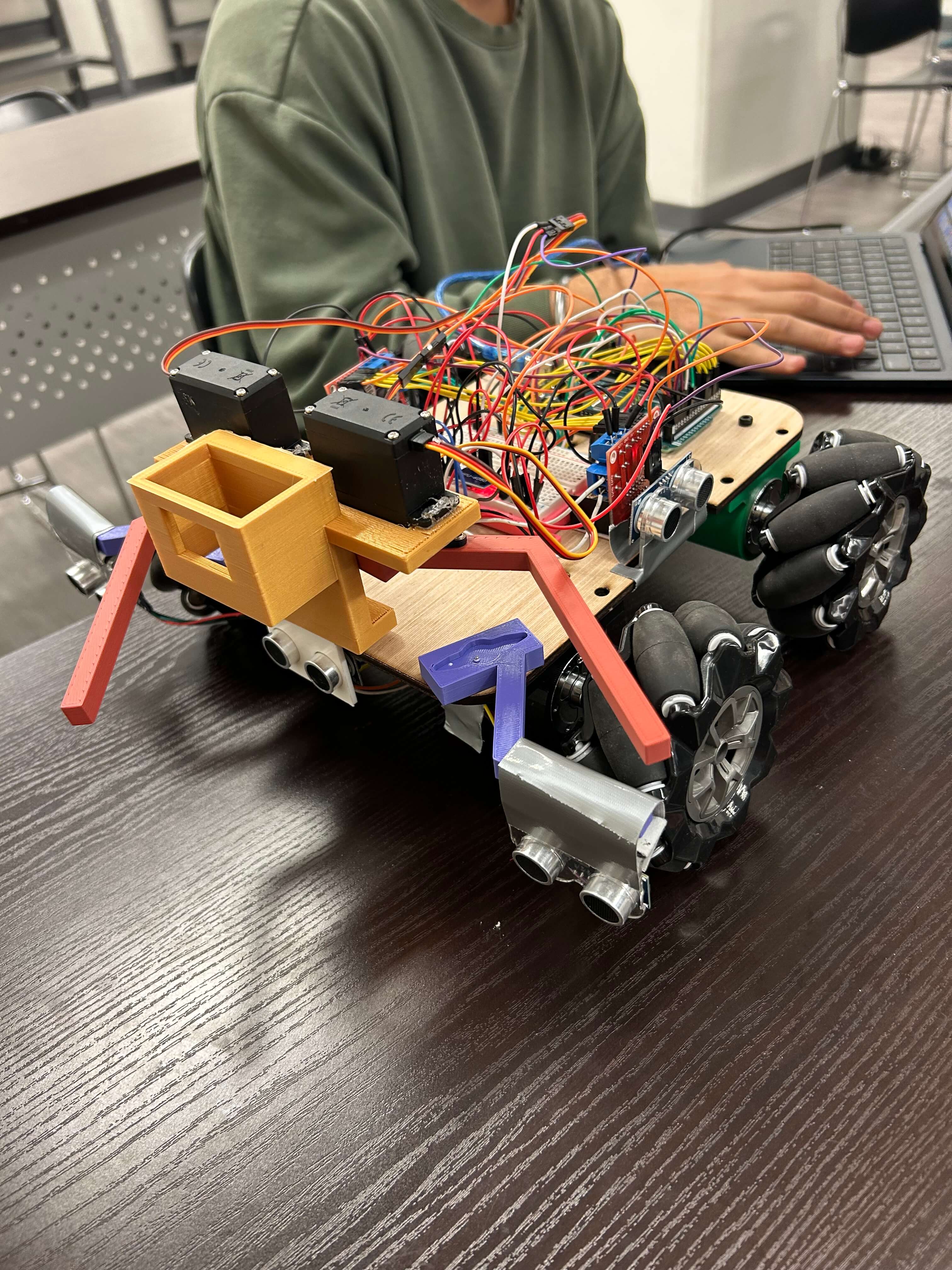

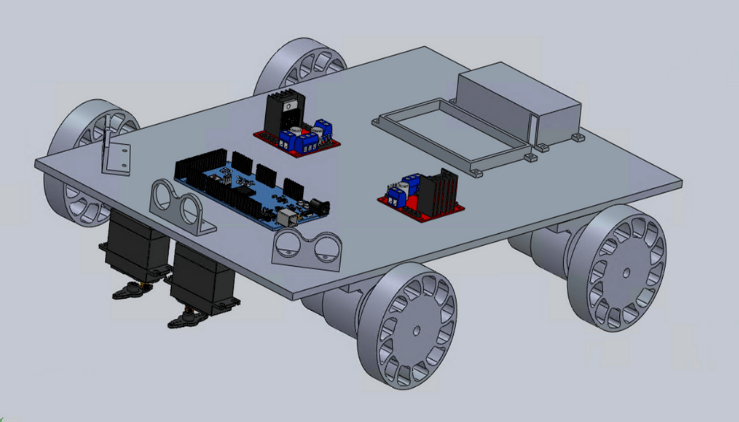

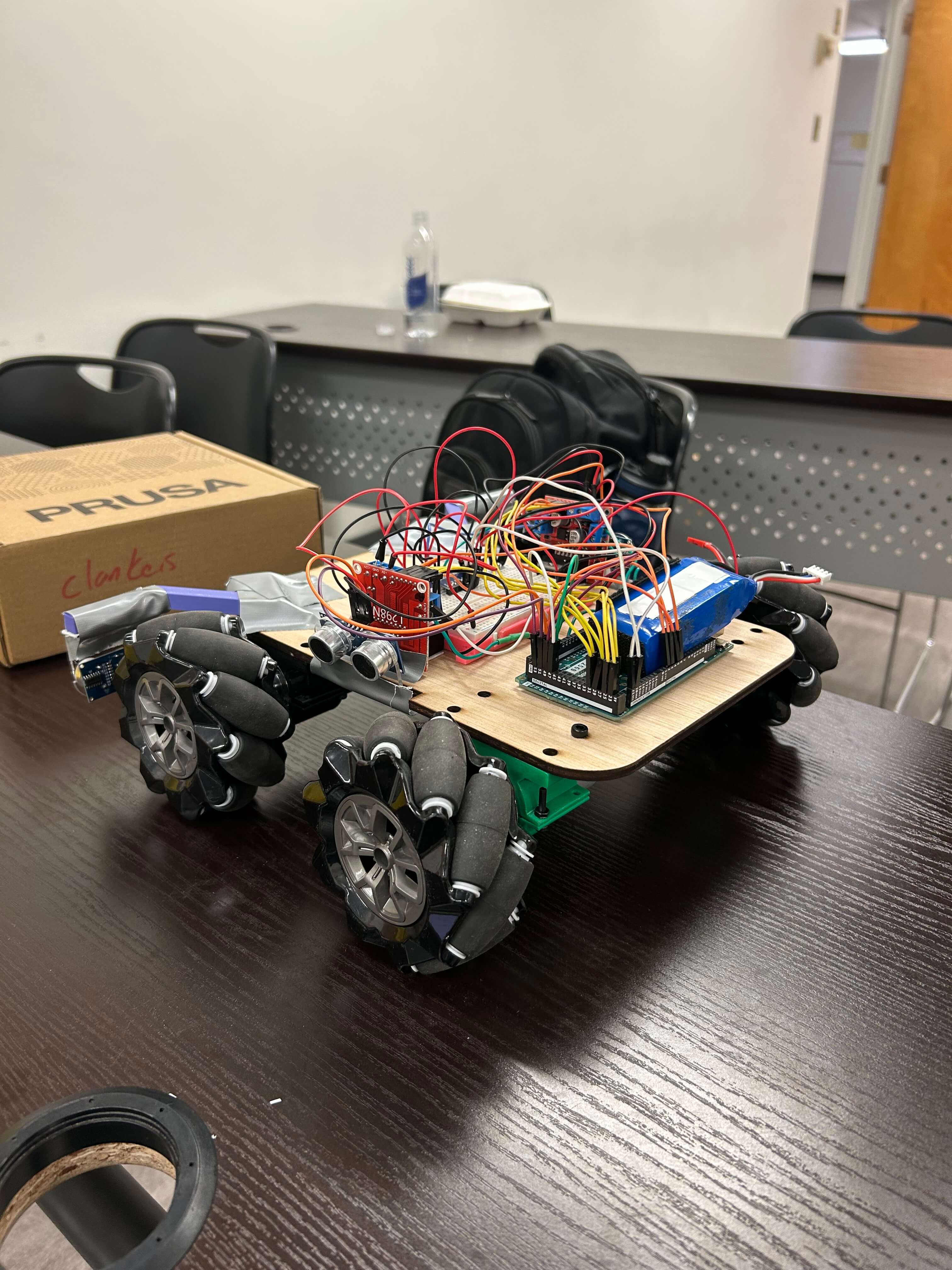

In this group project, I took intiative in designing and 3D-printing the claw mechanism used to grasp the yellow cylindrical target, as well as wiring electrical components. I also planned to use a color sensor for searching the target by designing a front-facing slot for the component and writing the necessary code. However, during testing we found that the sensor's effective range as too short for reliable use, so the sensor was excluded from the fianl build.

We went through several iterations of the claw design to ensure it was strong enough to lift the cylindrical object without failing. Out initial version placed two servos beneath the chassis, but this approach lacked enough torque and had no reliable mounting method.

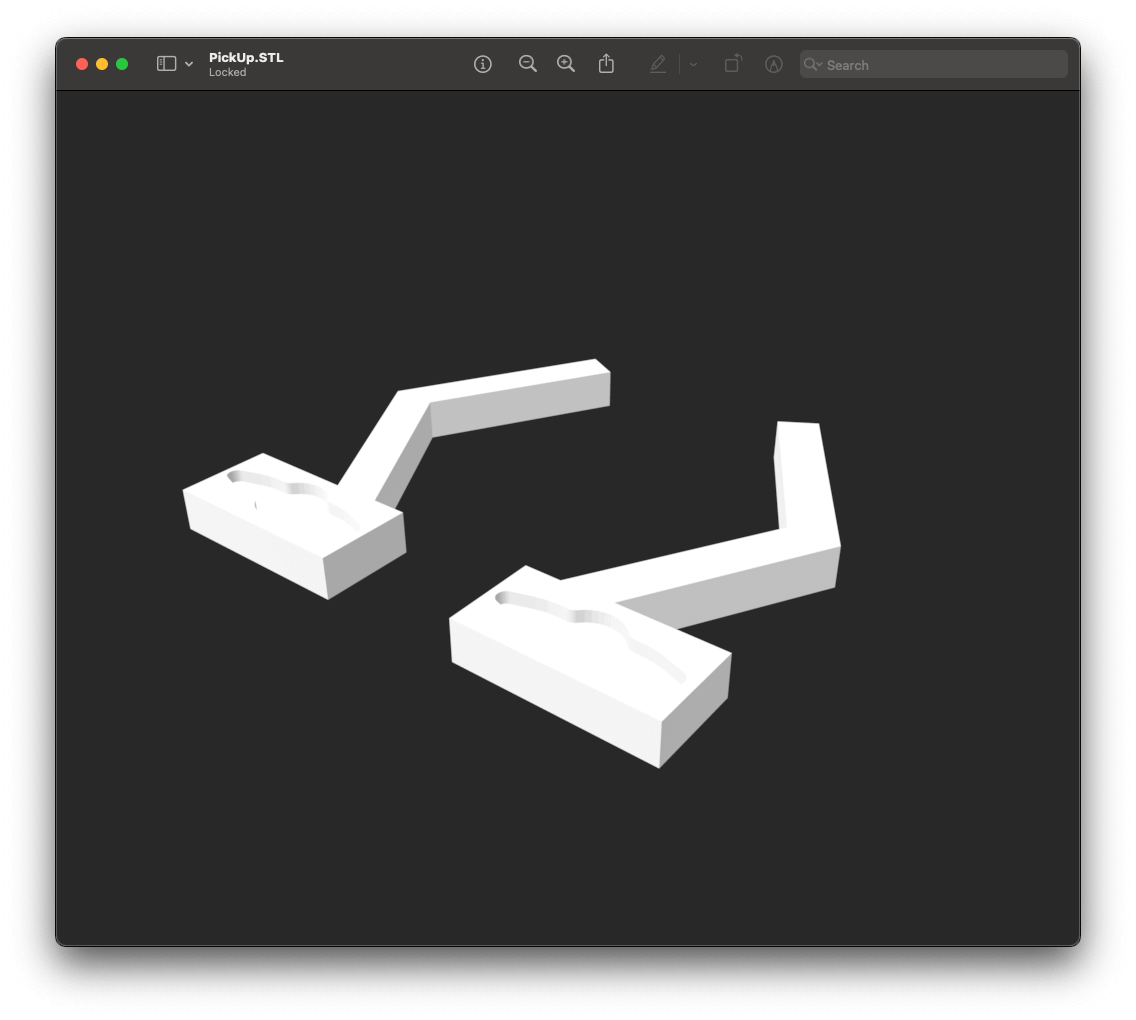

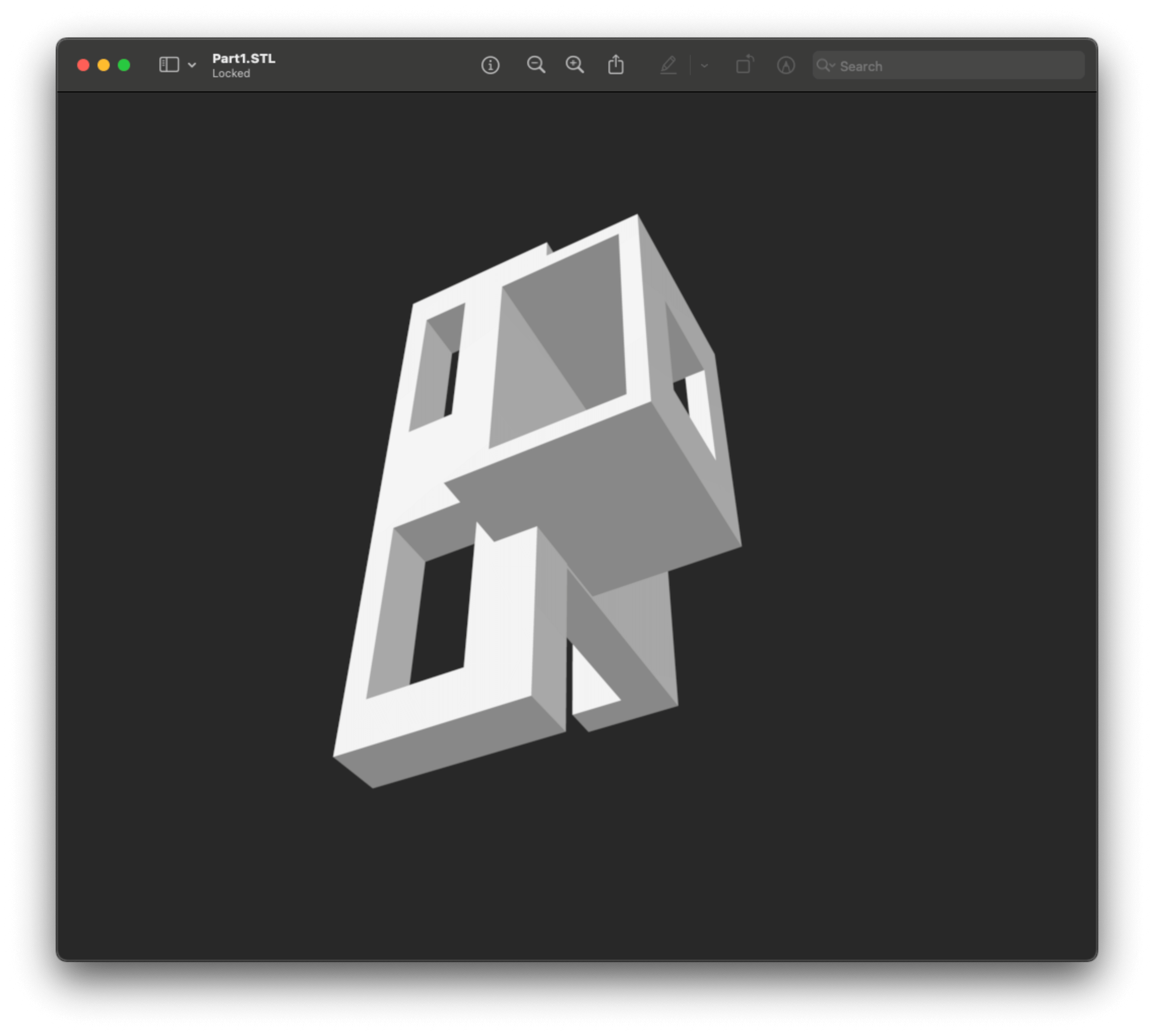

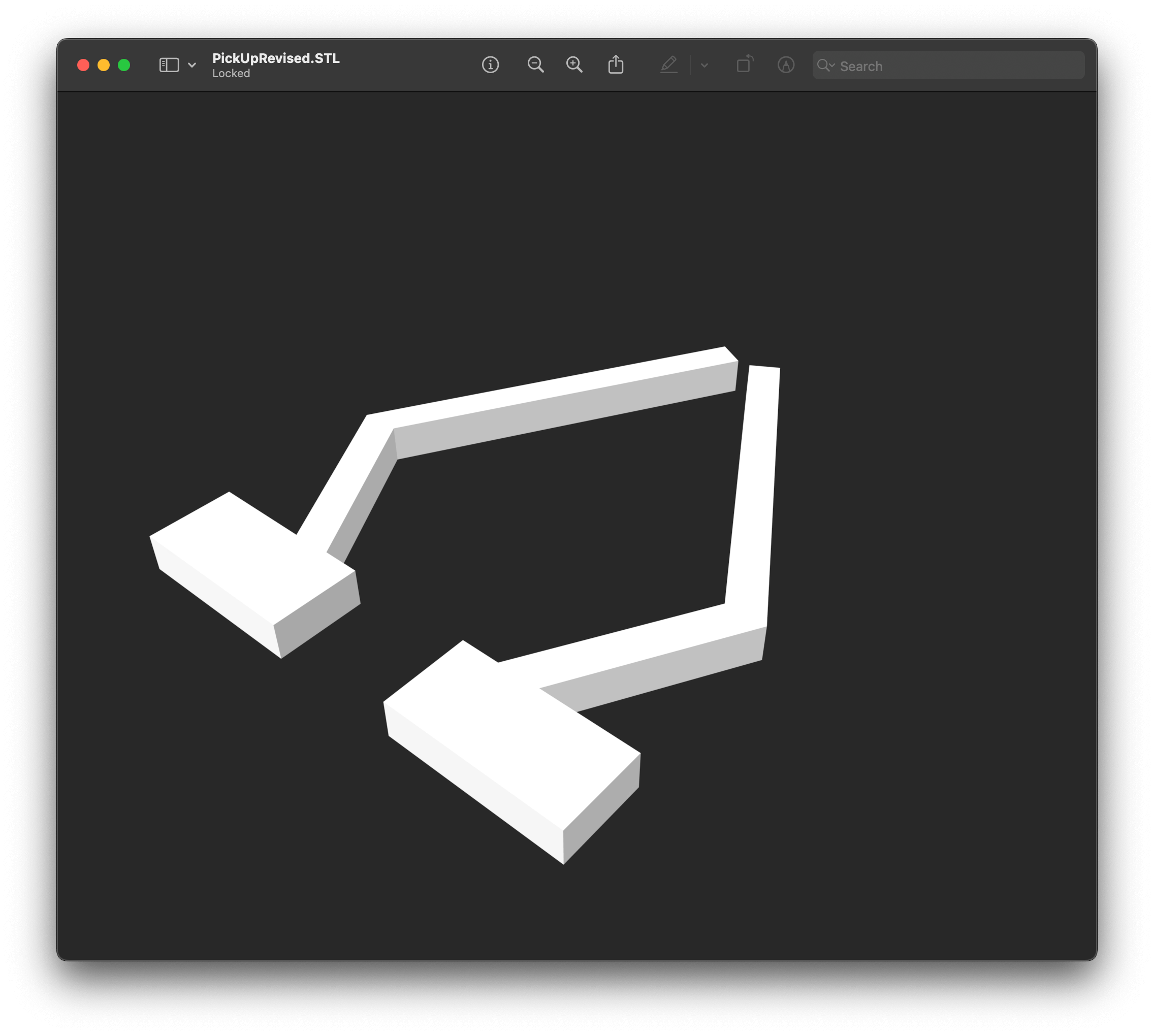

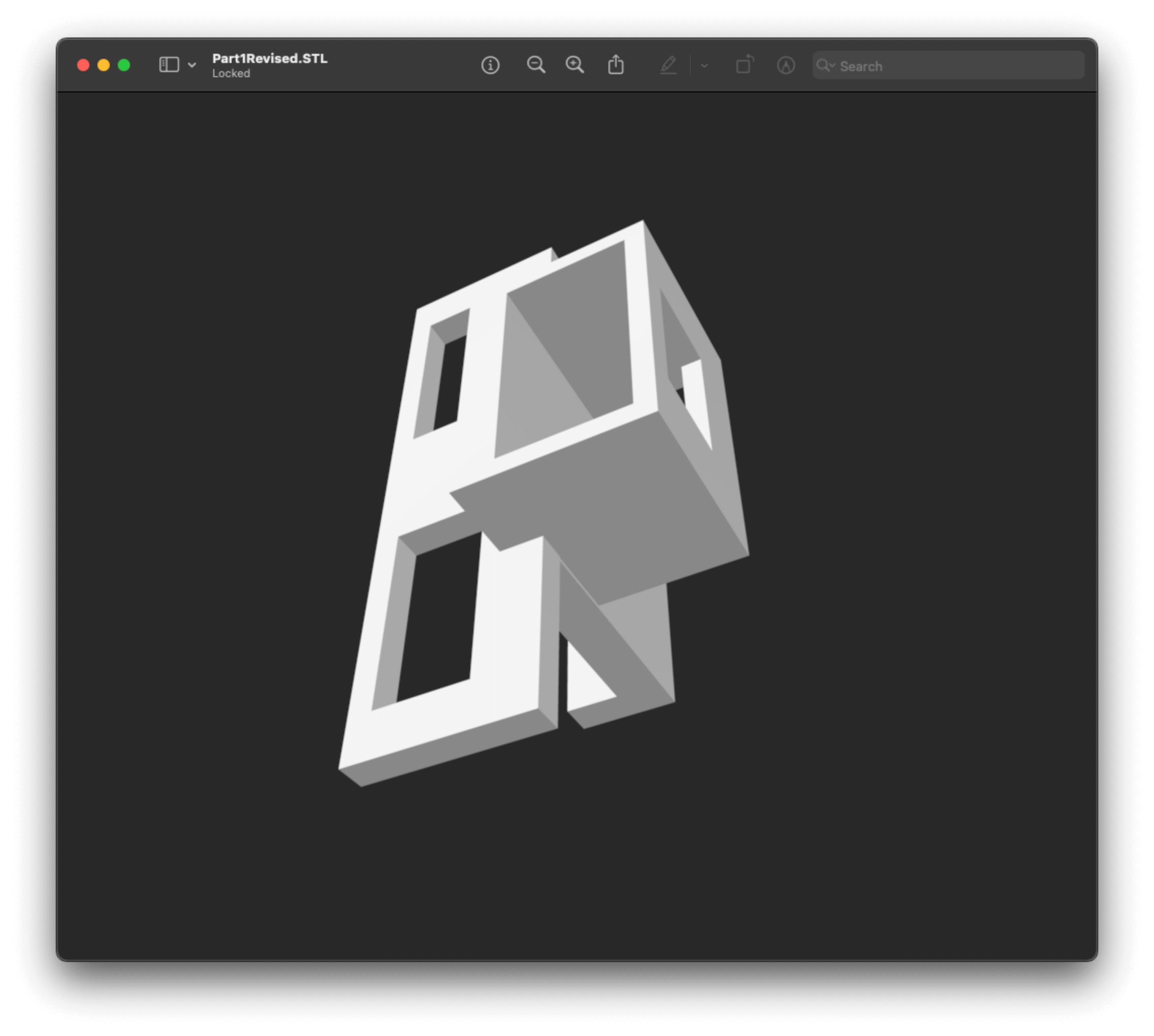

After brainstorming a few ideas, including a suction-based design, we settled on the most straightforward solution. This involved designing a dedicated servo mount supporting two servos, each controlling a 3D-printed arm to grasp the cylinder. To create these, I used SolidWorks and printers from the UCLA makerspace.

During assembly, we found that the servo dimensions provided in SolidWorks did not match the actual servos, which meant the printed arms could not be attached and were unusable for gripping. At the same time, we noticed that the ultrasonic sensors could miss nearby walls when mounted near the center of the rover (they have a narrow field of view of about 30°-60°). Thus, we repurposed the printed arms as forward mounts for the ultrasonic sensors, and we placed them in front of the wheels to improve wall detection (these are the purple mounts in the images).

I redesigned the arms without the attachement indents so they could be screwed directly into the attachments. I also modified the mount to increase the claw's range of motion.

After implementing obstacle detection and navigation logic, we were able to autonomously move through the course and avoid walls.